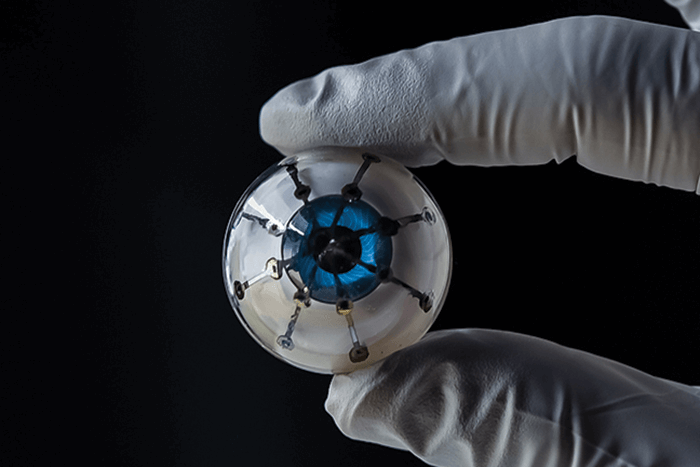

In the quest to beat blindness, a team at the University of Minnesota, USA, has successfully 3D-printed a “bionic eye” (1). The hemispherical photodetector array is made of five material layers, and can be 3D-printed in an hour under ambient conditions. “The organic photodetectors are the active layer, and translate optical information into electric readout through excitation from external light,” explains Ruitao Su, one of the researchers working on the project.

The team, which holds a patent on 3D-printed semiconducting devices, measured the efficiency of light-to-electricity conversion by calculating the ratio between the number of generated electrons and incident photons – known as the external quantum efficiency (EQE). The photodetector performed admirably with an EQE of 25.3 percent. “The high efficiency of the photodetectors, and the ability to readily customize the design size and layout, demonstrated that 3D-printed optoelectronics have the potential to match those of microfabricated devices,” says Su. Unsurprisingly, the bionic eye is still a long way off being useful to patients… “A vision system with on-board power supply and interface to visual neurons needs to be developed first,” says Su. “We also need to verify our ability to print the photodetector array conformally onto eyeball-shaped soft tissues, and conduct experiments to validate biocompatibility and functionality.”

References

- SH Park et al., “3D printed polymer photodetectors”, Adv Mat, [Epub ahead of print], (2018). PMID: 30151842.