The need to produce smaller, more sophisticated drug or drug-delivery particles presents a challenge to pharmaceutical manufacturers. So, how do you guarantee high batch reproducibility and dose uniformity on a commercial scale? Simple – you look to the industries who do it best. Or at least, that’s what Aerie Pharmaceuticals did when they acquired the rights from Envisia Therapeutics, Inc. to use Particle Replication in Non-wetting Templates – also known as PRINT® – technology in October 2017.

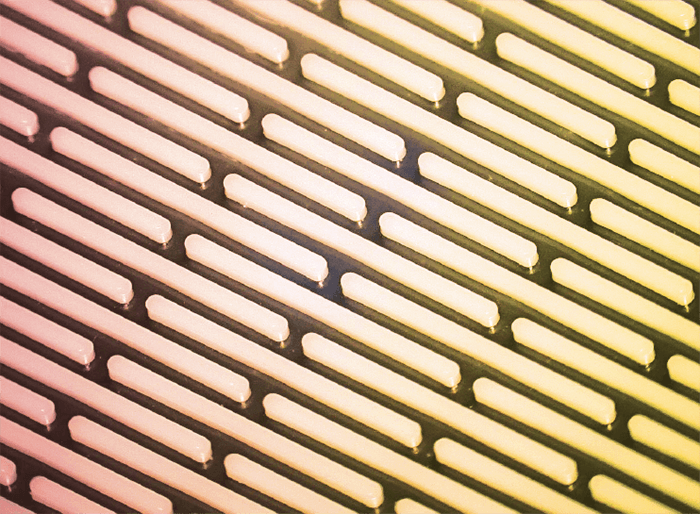

Integrating the precision of the semiconductor industry, with the efficiency and scalability of plastic films-based manufacturing, PRINT is capable of producing particles as small as a nanometer. It is compatible with a wide variety of drugs – including many classes of small molecules and biologics – and can be used to make combination products with multiple active ingredients.

Its versatility hasn’t gone unnoticed. Aerie is using the PRINT platform to produce injectable intraocular implants, composed of a bio-erodible polymer that steadily releases drug over 4-6 months, for its two lead clinical development programs in retina – AR-1105 (dexamethasone) and AR-13503 (Rho kinase/Protein kinase C inhibitor) – for conditions such as diabetic macular edema and neovascular AMD. Aerie is also evaluating the use of PRINT- produced sustained-release therapies in glaucoma and ocular hypertension. Watch this space.