Back in 2012, Brussels-based company HASA OPTIX embarked on a journey to produce single-use ophthalmic instruments that experienced surgeons could not differentiate from the expensive reusable instruments in their armamentarium. This mission – to make products that offer sustainable solutions, a better cost-controlled work environment, and increased quality of care for all stakeholders involved in ophthalmic surgery – was visionary in 2012. Today – following the impact of COVID-19 and a more decisive global shift to sustainable practices – the need for high-quality, recyclable single-use instruments is more crucial than ever.

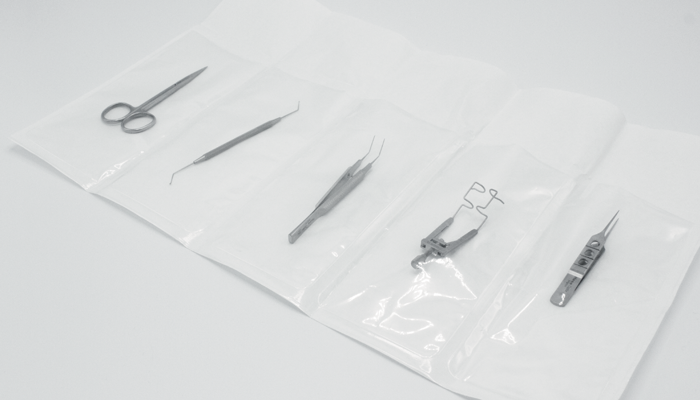

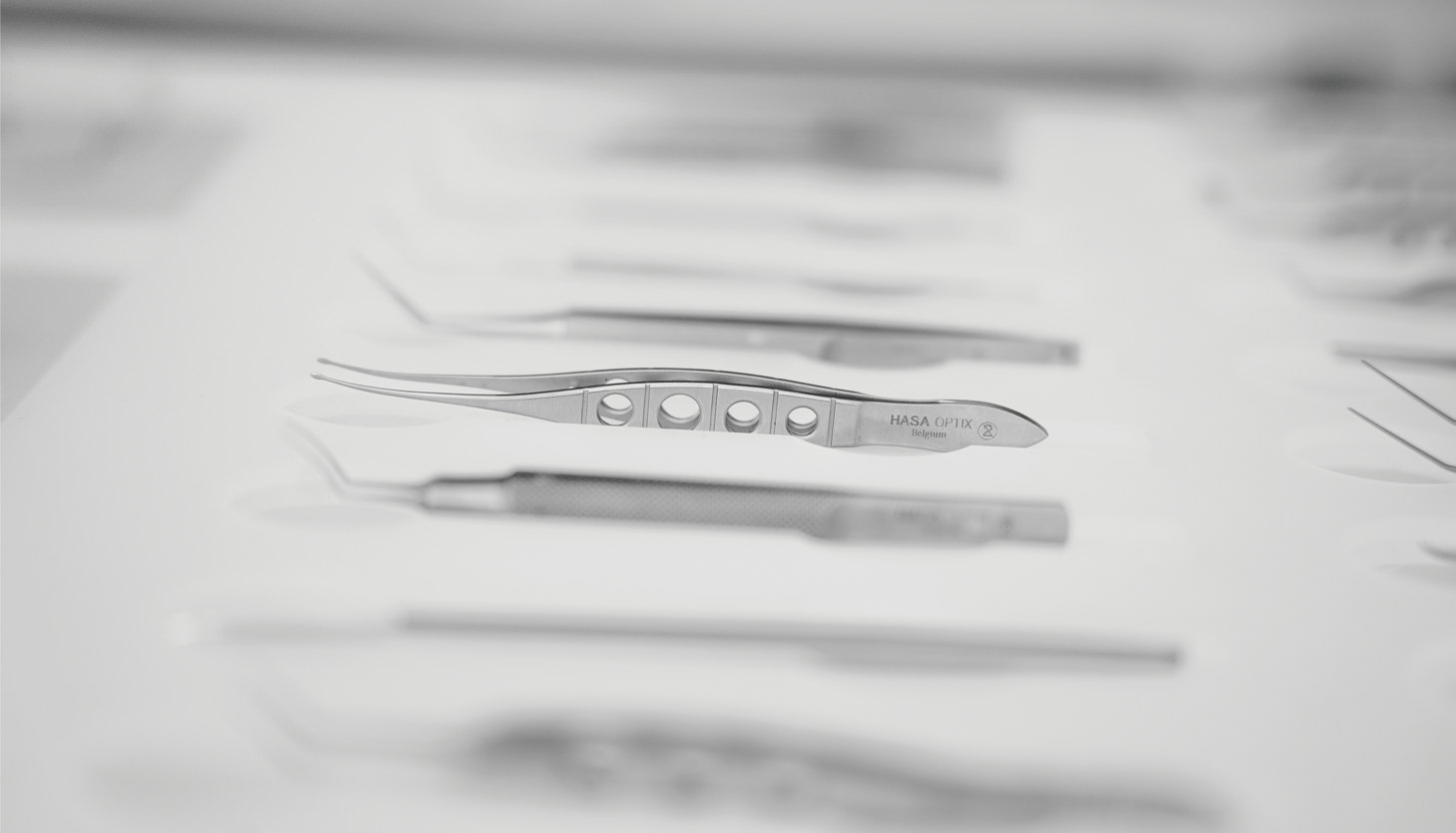

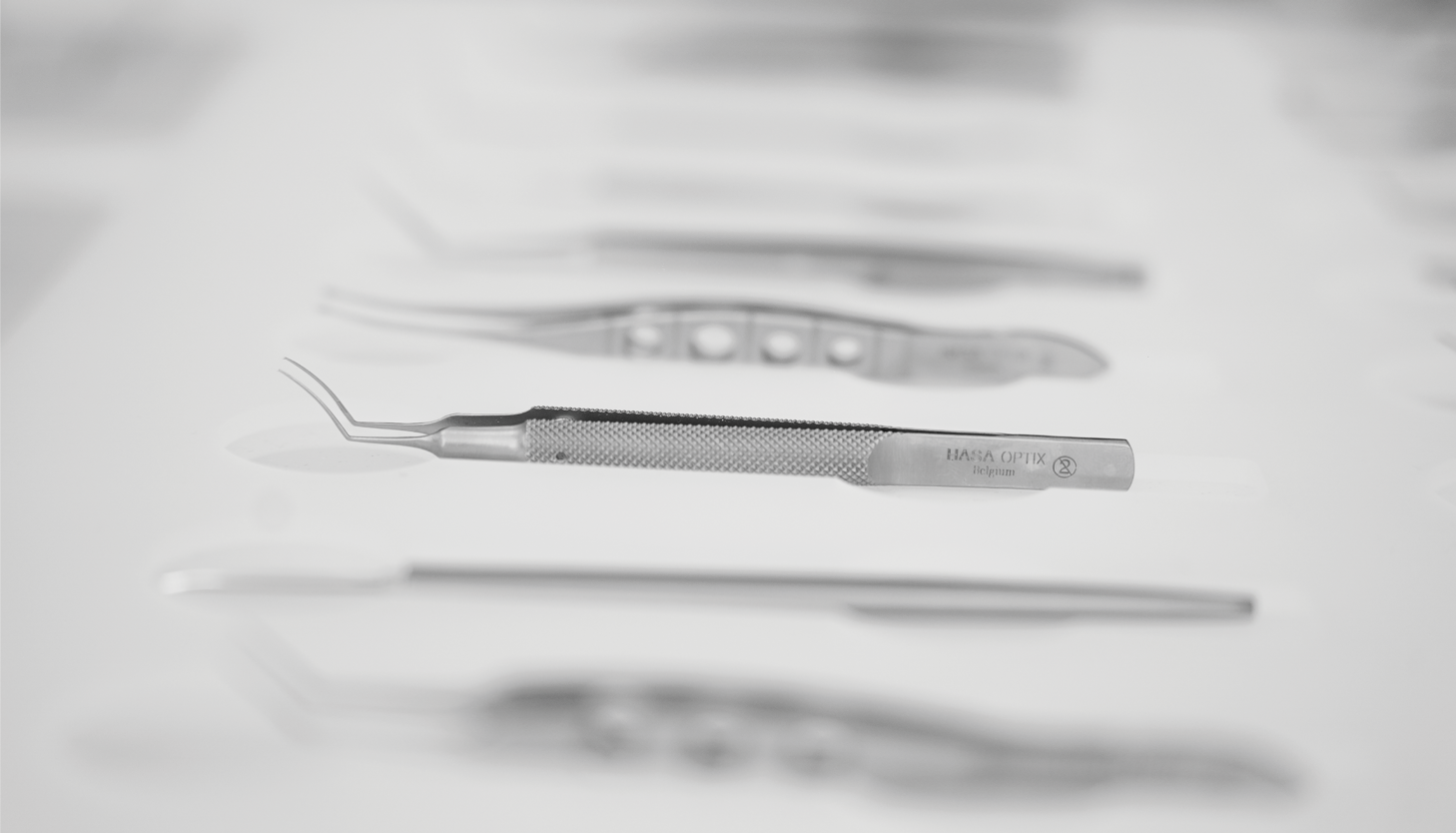

HASA OPTIX is the first company to make recyclable single-use instruments entirely of stainless steel. Precision-engineered, they have the same look and feel as reusable instruments, but eliminate the need for cleaning and sterilization management resulting in streamlined processes, increased operating room (OR) efficiency, and enhanced patient safety.

William Wiley, Medical Director of the Cleveland Eye Clinic and a pioneer of many eye procedures in the Northeast Ohio area, is a US board-certified ophthalmologist with experience of using HASA OPTIX’s instruments. Wiley says that the HASA OPTIX products “have seamlessly integrated into my workflow and seem clinically identical to my reusable instruments.” Among the clinical benefits the instruments offer, he explains, is a reduced risk of infection. “Sterilizing reusable instruments isn't always 100 percent effective” but single-use instruments “are sterile and reduce the risk of patient-to-patient contamination,” Wiley observes. “They contribute significantly to infection control by eliminating the risk of residual pathogens that might survive the sterilization process.” And with each single-use instrument being brand new, “surgeons don't have to inspect or test instruments for wear or damage before surgery [or] worry about damage during sterilization process,” he adds. As such, the surgeon is “always ready – and they can have confidence that the tool they're using is in its optimal state.”

Without the need for sterilization between surgeries, there's a quicker turnaround between cases, Wiley continues. This creates immediate cost savings, as there’s “no need for sterilization processes that involve time, labor, and equipment.” When a sterilizer goes down, “that can ruin an OR day,” observes Wiley. “But with single-use, you are always able to continue.”

As regards more long-term savings, Wiley reminds us that instruments that become damaged or degraded over time can be expensive to replace. However, “this isn't an issue with single-use instruments.” Indeed, as with sterilization and replacement, these instruments can alleviate the costs associated with repeated repair and storage. One particular HASA OPTIX instrument that stands out for Wiley is the IOL Cutting Forceps. This instrument is particularly delicate and easily damaged in a reusable setting, he explains. “One may not know until its needed if it has been damaged – thus a single-use version is quite dependable.”

While HASA OPTIX is “passionate about eliminating cross contamination and reducing risk management, while increasing efficiency, convenience, and reliability,” safeguarding the future of the planet is also key to its mission. As Wiley notes, single-use products can reduce the amount of water and energy that the sterilization process requires with reusable instruments. With the number of cataract procedures predicted to at least double in the next 30 years, the company’s approach to sustainability, waste management, and cost-containment gives HASA OPTIX a head start in the practice of responsible eye treatment that also supports the shift to a cleaner environment.

Looking to the future, Wiley believes that surgeons and hospitals could increasingly adopt single-use instruments due to their advantages – “setting a new standard in the field.” With competition and the need for differentiation inevitably spurring more innovations in ophthalmic surgery tools and techniques, HASA OPTIX – with its commitment to premium quality, sustainability, reduced risk of infection, and cost control – is taking a clear early lead in this new era of single-use instrumentation.

US-HASA-2300020 09/23